If you are in the unfortunate position of having a broken Canon MX700 all-in-one printer this is for you. Correction: if you have a broken Canon MX700 and you are foolish enough to want to try and fix it yourself, this is for you. Especially if the print head is stuck on the right hand side, and you get error 5100, or error 6a80, or a loud screeching noise. I realise therefore that this post is of interest to very few people.

Never mind, it gets worse. This unit is not all that easy to take apart, and most things are clipped in place rather than screwed. It is very likely that some clips will break when you take it apart. It is also very possible that once you have taken it apart you still will not fix it, or that you will make it worse by breaking more things. I can also guarantee that you will get inky fingers, because I doubt you will be successful fiddling about with innards of this printer wearing gloves, and probably broken fingernails.

Unless of course you are a Canon engineer and do this all the time, with the benefit of a service manual if you need it, in which case perhaps it will afford you some amusement.

Note: if you just have the 5100 error but the print head unit is not stuck, you might not need to disassemble the printer. Many have found that simply cleaning the timing strip is enough. See here for details. Another common problem is paper jams. Do not resort to disassembly unless you really need to do so.

Please do not proceed unless you understand all of the above and will not blame me for the continuing malfunction of your printer, or its damage beyond repair.

Now with that out of the way I will tell you how I fixed my MX700. The story goes back some time, to when I got error 6a80 and ranted about the price of ink cartridges. At that point my print head was not stuck on the right hand side – in fact it was parking itself incorrectly on the left. I reached the point of discovering a sliding part on the right that temporarily fixed the 6a80 error, and enabled the print head to park correctly on the right, but it went wrong again if I tried to print. I left it alone until I had a few spare hours.

That was today. I needed to make a photocopy, and my spare printer is not an all-in-one, so I set about trying to fix my MX700. I poked around a bit on the right trying to ease the plastic moving parts, but I did the wrong thing somehow, and instead of error 6a80 I had error 5100 and the print head was stuck firmly on the right. Bad.

Just to explain, if the print head is stuck on the right it is pretty much inaccessible. You can rock the print head or tug on it gently, but that is about it.

Of course I Googled. Some solutions said to remove the right panel, but I could not see how to do that. One guy said he successfully took his MX700 apart but did not say how. I decided to have a go. Here is how I did it.

First disconnect all cables. I don’t really need to say that, do I?

1. Remove the right and left silver side panels. Start prising them apart at the top; it may help to tug up on the little tabs you can see on the inside. They are just clipped on and eventually pull away. Remove the silver panel on the front right corner too.

2. Remove the hinged front right panel that covers the card slot. Try not to break the bottom protrusion that forms part of the hinge. Also remove the small black panel at front left.

3. Undo the four black screws on the back of the MX700, and one black screw from behind each of the front panels you removed in step 2. On the right-hand front panel, remove the small part that was attached with the screw you have just removed.

4. Now you can prise off the main black side panels on right and left. I found this tricky. Use a flat blade screwdriver to release two tabs marked with arrows on the inside top cover. The left hand panel I found easiest to start releasing at the back near the screws. I don’t have any easy way though, just use the right combination of tugging and prising until it comes free.

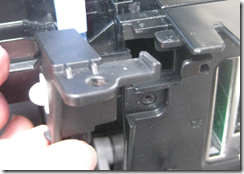

5. I am sure you have noticed that the top unit which has the scanner glass and top sheet feeder is still attached. Now you can remove it. The first step is to detach two connectors at the back left corner:

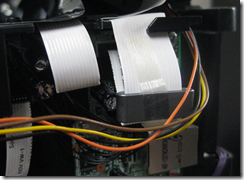

and to unplug the two white ribbon cables at the back right corner:

and unplug the connector towards the front of the right hand side logic board to which those yellow, brown and orange wires above connect.

6. Now unscrew two silver screws from the large toothed hinge at the back left, which you see when the top unit is raised. Once these screws are removed you can lift off the top unit, but take care, because the smaller of the two white ribbon cables is clipped in place at the back right. You need to thread this out from under those clips before you can safely lift the top unit free of the bottom unit.

7. At this point you can place the top unit somewhere safe and congratulate yourself – first phase completed successfully.

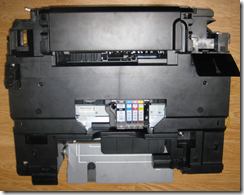

The next step is relatively easy. First unplug the small two wire connector at front right, with cables that run into the top black panel. Then remove four silver screws from the top black cover – one in each corner – and prise it off. Pretty easy compared to the side panels.

At this point if you are lucky you can persuade the print head unit to slide to the left and inspect the right hand area, which has all sorts of interesting features.

If you gently rotate the large gear on the right by pushing it back along the top – in other words, counter-clockwise as seen from the left – you can see the wipers move forward and back and the purge pads rise and fall. The wipers can get stuck in a forward position; this is one possible cause of the 6a80 error. I took the opportunity to do some cleaning up and to apply a little white lithium grease to the plastic moving parts – take care not to get this on the wipers though. I made sure the print head was moving freely, then I re-assembled the printer and hoped the job was done.

Re-assembly by the way is pretty much the reverse of disassembly. The hardest part is threading the white ribbon cable back into the clips at the back right – you have to hold the top unit in one hand while threading the cable with the other, or get a friend to help, or do your own thing with imaginative supports.

Unfortunately in my case after I re-assembled the machine it STILL DID NOT WORK. The print head promptly got stuck again on the right. I did not give up; I took it apart again and went even further. So read on if you want to know more.

When I got back into the cavity on the right hand side where all the action is, I noticed a spring out of place under a white plastic arm on the right. I corrected this, re-assembled, and it STILL DID NOT WORK. I got loud screeching, then a 5100 error. I was about to chuck the MX700 in the skip, but read something on the web about the screeching being caused by a dirty timing strip. Was it worth a third attempt? Maybe. I decided to have a go.

This time I had real difficulty persuading the print head to budge. I removed the ink cartridges and lifted out the print head so I could put it out of harm’s way. I also found a tiny spring rolling around and did not know where it had come from. All bad news. Finally I pulled with considerable force on the print head unit. It moved to the left, but also a strip of white plastic came free. While this was depressing, I did notice that the white strip included a notch that matched the tiny spring. Maybe bad news could be good news.

Clearly the whole print head unit would have to come off. I discovered the way to do this.

First, remove the delicate timing strip. This is easily done; just unclip it from the springy clip at the right and pull it out. Note that it goes through the print head unit, not just behind it. Put it somewhere safe.

Next, note that the rail on which the print head slides is held on by three screws. Undo these screws, and the rail comes away. Unhook the rubber geared belt which drives the print head unit along the rail. Note that the belt remains attached to the print head unit. Now you can remove the rail and the print head unit, though I actually left the ribbon cables attached so it was not completely free.

It took me ages to puzzle out how the white plastic strip that had come away should attach to the print head unit. I can tell you that there is only one sensible way it can go. I removed the other white strip with its four springs (beware losing the springs, they can jump anywhere), then fitted the other white strip with its own spring, then the other white strip, then I replaced the four springs. I hope you will not need to do this.

At this point you can do a lot of cleaning up. I cleaned the rail, and I cleaned the timing strip. I also cleaned the inner print head which was gummed up with ink. I reassembled, and put a little new white grease on the rail. When you replace the timing strip make sure no ink gets on it, and note once again that it goes through the print head unit and not just behind it. Make sure the print head unit travels easily on the rail.

I reassembled one last time. With no great expectation I turned on. Humming, whirring, no error. I did a test print.

Amazing. Well, I admit there are some funny smudges on the print and I don’t know why. Still, it is a big step forward from error 6a80 or loud screeching. Maybe I can fix it …

Thank you so much for taking the time to write this down!!! All worked out fine, and best of all, my printer is working now. Yey!!!

Thanks for taking the time to put this out there. It turned out it was the little white sponge thing that got stuck in a forward position. this helped me to get at it. I’m thinking of leaving the sides off now, it’s a nice little FrankenPrinter.

Thumbs up!

Very nice guide, just finished reassembling my printer after a 6a80 error and it works wonders again!

Thank you very much!

Tim

I got to the point where I removed the two “silver screws” which seem to hold the hinge for the top unit.

My top does not seem to want to lift cleanly. It is still “stuck” at the back both on right and left. All wires removed and clear of retainers. Also there was a black “paper” at the back right which had to be removed.

I need to replace carriage but don’t want the damage this otherwise new printer.

What am I doing wrong? Did I miss a step at the back of the unit? I could send pictures of where I am at if it would help

Thanks

Howard

Howard

You removed the two screws from a black part with a + sign between them, right?

As I recall it just lifts off then, if you have detached the other wires.

Don’t force it though, see if you can work out what is catching. You may need help from another person as this is where a third hand comes in handy!

Tim

Tim

I lifted it off by gentle wiggling. You are correct a second set of hands would be helpful.

Bottom line is I replaced the carriage and the unit works like new (it is supposed to be new). It was advertised as a “new bulk” but was an item that had been opened and operated. Might have been a demo or RMA. It was from a vendor who shall go unnamed (but I will not use them again). Their rules were 48hrs for return of a DOA unit. A number of the male pins (that talk to the print-head) on the face of the carriage were smashed backwards and could not be straightened.

My experience :

1. No matter how careful I was (used auto trim tools) a couple of the “tabs” broke on the panels. I’m old enough that I remember when autos were completely bolted and screwed together. 🙂

2. I found the most difficult part was removing the rail that the carriage ran on. It had a long tab on the right hand side so it could not be lifted out. I ended up running the carriage all the way to the right and then was able to angle the rail in such a way that I could remove it. In doing that and in removing the carriage I broke the hinge holding a small hard curved white plastic “bar” that sets just forward and above of the ink pads. It did not connect with a switch and I am not certain exactly what it does but looks like it might act to press down on the upper front of the printer head allowing a firm contact with the pads when the unit is parked. I guess that I will have to see if my nozzles dry out faster than they normally would.

In replacing (and probably in removing) the carriage belt it really helped to release the spring which puts tension of the left hand wheel the belt runs in. Than made re-positioning of the belt very easy.

Anyway I wouldn’t have attempted the job without your instructions. The printer works perfectly at this point and the only issue for me is the little white piece that I broke the hinge for.

Tim,

Great work if somewhat complicated for the frightened.

Would you know how to correct error 5B00 on the MX700 please?

Linda

A brief search tells me this might mean “waste absorber tank full”. Sorry, I don’t have a fix for that specific error.

Tim

That is the catch tray right under where the cartridges rest. All printers have them. It’s just a matter of taking paper towels and dabbing the ink out of the sponges. I suggest wearing gloves when you do this as it is a VERY messy job.

I’m getting the loud screech with Error 5100 on my MP610. I’m praying no plastic gears or fragile wires are getting stripped each time this happens.

This is the first/only place I’ve heard that “screeching” may occur simply due to ink/dirt of the transparent guide strip. I was assuming the ink tray was hitting a physical obstacle of some sort (no foreign objects or paper jam).

I’m not handy enough to try and disassemble the printer, but I’m hoping now I can fix it by simply cleaning the guide strip. I just wish it was easier to get to. 🙁

(Suggestions appreciated.)

Quick question:

Shouldn’t I be able to slide the print head/carriage smoothly all the way across with my hand when the printer is off?

Mine seems to scrape over some metal “railroad tracks” before hitting a brick wall about halfway over. I’m trying to figure out if something was dislodged or shaken loose in shipment.

Yes, normally it should slide smoothly I would have thought.

Tim

Thanks for the info.

I am having an issue with no power. I figured out that the the AC Power Adapter located on the bottom of the printer, where you plug in the power cord, has two tabs that can be pulled outward to release the power adapter. Inside a cable is connected to this power adapter. Maybe I have a fried power adapter, or maybe the whole printer is gone. I had the power cord tested and it is supposed to be good.

Thanks for the helpful guide. I am having the same problem as Andrew above and needed a guide to getting inside the beast. Really want to get it back up and running as it had been a great unit up until being suddenly stone cold dead.

I’m thinking about replacing the power supply on this thing…I heard a pop when it was plugged in and now as soon as I plug it in it shows a solid power light but nothing else comes on-screen. The thing had issues with print quality and crooked prints ever since I got it, and no amount of troubleshooting ever worked. Does anyone know how to get ahold of a new power supply? Thanks for the instructions. I’m sure they will be useful!

I had an MX700 ink absorber full reading and trying to stay away from the difficulty of dismantling the whole machine and still not being able to get to the absorbers, I placed the machine on it’s back surface with the bottom facing me, drilled a series of 1/8″- 5/32″ holes (about 70 or so, close together) around the marked rectangles not too deep (1/4″). Then used a utility knife to cut between the drilled holes. That panel came out and the absorber pad was there. I pulled it out with pliers; note the pad encircles several supports, so it got ripped out and was OK. After a through washing and drying, I slipped it back in, taped the removed pad in place with 3M 33+ electrical tape and ran the machine. But the error code came back, just push “OK” and have to do that one time, each time the machine is turned on and start printing. Just a suggestion, it may help.

HI WHAT IS THE SIZE OF THE PIECE YOU DRILLED OUT ?

THANK YOU THANK YOU!!!!! THANK YOU FOR THE WONDERFUL GUIDANCE! IT WORKED..

Anybody know why my cannon mx700 won’t print. The paper goes through the printer and the printer sounds like it is printing but the paper comes out blank?

I tried the ink jet cleaning but it still doesn’t print. Any suggestions?

Thanks

The paper goes through the printer and the printer sounds like it is printing but the paper comes out blank?

All I ever wanted to do was replace the pads. These instructions only get you half as far as you eventually need to go, if your goal is to find and replace all the pads in all 4 locations. But even this partial set of instructions is way better than nothing. It sure helped me. These instructions actually cover the most difficult initial stages of disassembly. Further disassembly is straightforward removal of screws. Except for one buried way down deep in the center. To remove that final screw, you need to first remove a screw holding a rail ensconcing some wires along the top. Only then will you see the head of the screw buried 4 inches deep holding the final assembly onto the last plastic bottom piece you need to get to to get to the biggest, most irregularly shaped pad of them all.

There are 4 different places where pads soak up ink. One of them can be accessed in the back at the bottom with no other disassembly. There’s a spring-loaded panel which, when removed (a bit tricky ’cause the direction to remove is opposite what you’d think) reveals 2 pads. Both were completely soaked with ink. I didn’t find out I did not need to disassemble everything (at least for this particular pad – actually two sets of folded-over pads) ’til after I’d disassembled the whole printer. Another one is right next to the Ethernet/phone port. You might be able to pull that out with tweezers after only a partial disassembly of the outer shell. The other two locations – one very small and completely untouched by ink – and the other one the biggest one of all (comprising 1 large pad and another smaller pad on top) were quite thoroughly soaked and I don’t see how anyone could possibly remove and replace them without almost completely disassembling the machine. There are also a couple thumbnail-size, stiffer wafers – maybe as thick as a quarter – under where the print head normally rests that I discovered after partial disassembly. At first I was all excited ‘cause I thought these were the vaunted ink pads. But, no, most the pads you’re after are over 6 inches long and a couple inches wide and maybe a quarter inch thick – often folded over and doubled or quadrupled to make up almost an inch of thickness.

You can buy a pad replacement kit (QY5-0192-030) here: https://www.executivecolor.com/item.asp?item=1484194. You really don’t want to try to rinse out all that ink. Trust me. I tried. You’ll only end up with wrinkly, torn, deeply stained, yucky inkpads.

The nice instructions to clear the “ink pads full” error you find sprinkled all over the web (such as at http://resettercanon.blogspot.com/2010/09/canon-mx700-printer-error-code-5b10.html) only work when you do one thing they neglect to tell you and which they assume you know: you must have the ink cartridges in place. If you took the whole printer apart to replace the pads and want to test it before you snap the final hard-to-remove shell back together and before you think to put the ink cartridges back in, the procedure below will not work. Specifically, you’ll never get the “Idle” in “Service Mode Idle”. So you can go through this procedure several times and it won’t “take”.

I have the same problem as George. Everything appears to work correctly but the paper comes out blank.

After couple weeks idle, I need copy & was printing out blank paper; then now the power will not come on. Could anyone help?

Tim,

Correction, I moved the print head to the LEFT to be able to get at the rail screw

Fred

Tim,

Thanks for the great instructions. I had a 6a80 error with the printer head stuck to the far right. Upon dissassembly, I found that a small white spring-loaded plunger beneath the head was preventing it from moving. I was able to force the head far enough to the right to be able to access the plunger with a screw driver, depress it and free the print head. I moved the head to the right and then was able to access the 3d rail screw and remove the rail and print head assembly. I found that the spring-loaded plunger was on a pivot, and I suspect there is an actuator that disengages the plunger when printing is called for. However, I can’t access this actuator, and in fact can’t even see it, as it is buried behind the wall that the rail mounts to. Any comments or suggestions?

White plastic and springs – sounds like the bits I tangled with. It is like one of those puzzles; if you get all the pieces there is only one sensible way they can fit together.

Tim

Impressive write up! You save me from thinking about attempting this. I had an error 6a80 – I had a locked print head that was stuck on the right side – I was about to toss the entire printer. I cut a flat, thin, stiff piece of plastic from a fruit container – about inch wide by four inches long. I slid it under the print head and moved it forward and then to the back a few times. I powered it up and everything works!

Everybody try this first since it is so simple

I tried a piece of plastic as described above however that did not work. I then used a long thin paring knife and that did the trick. Slid it to the right and up and then backwards towards the rear of the machine. Did this several times and it finally worked.

Great tear down tutorial. The plastic snap locks are a bit of a nightmare but true to form it all comes apart with a bit of manipulation.

However, when re-assembled I turned it back on and everything starts to engage, the screen doesn’t come on though and then after about 15 seconds a loud clicking sound starts. It appears to come from the scanner plate, the scanner comes out about an inch or two and then retracts. It looks like when it retracts all the way the motor tries to keep going and thats when the loud clicking starts. It didnt do this before taking it apart. Any suggestions??? Thanks, Jason

Can you tell me the best way to clean the print head. I know it’s clogged and don’t want to spend $100 to replace it. Better just to replace the printer if required.

Thanks.

You can use hot water but make sure that you dry it out before replacing, a warm (not hot) hair dryer can help. Don’t rub the delicate connections.

Tim

I have Canon MX700. When I turn it on. I does not have power on. I tried some of way, such as go differnt outlet, change electric cable. It still not power on. Please help me to solve this problem. Thank you. J.P

Pull the plug. Hold the On/Off button down for one minute. Plug it back in and your power will be back on when you press the On button.

Best to disassemble and test whether the power supply is working with a multimeter, if you are up to that.

Tim

I am proud to advise that I have changed the absorbent pads on my MX700. That makes me a member of an exclusive and elite group. Perhaps there should be a t-shirt? Having gratefully been guided by Tim’s detailed account, and then encouraged and helped by seminarcr who refers to the hidden central screw, which is vital information, I successfully renewed my ink absorbers, and the printer still works. So I believe I can contribute some helpful suggestions

· When I was re-assembling I took a careful look at the annoying outer covers. I noticed that if I clipped the silver covers onto the black plastic covers before they were on the printer no access was prevented, so I assembled using this procedure. And so I suggest that taking apart could be done leaving the silver covers in place. Both main black covers are secured by 1 screw at the back, and both have 1 screw in front that also must be removed. For the left side the small black cover that faces the front must be removed thus exposing the front screw. Having looked at the inside of the black covers (on both sides) it seems to me that the top should be prised apart first. On the right side the hinged door at the front must be prised out very carefully. It must be possible as I replaced it last. Once it is out the exposed screw must of course be removed.

· For those like seminarcr and me needing to dismantle further to access the ink absorbers seminarcr mentioned that when a large number of screws are removed the whole remaining structure easily lifts out. This structure is secured to the base by 3 different types of screws. The commonest is a self-tapping screw, screw A. There are a small number of a similar but smaller screws, screw B and there is one screw with machined thread, screw C.

· Along the left side there are 5 x A. One of these is partly hidden by the power unit.

· On the right side there are 6 x A, 3 x B and 1 x C as follows: There is a vertical circuit board at the rear right corner that is secured by 2 x B screws. At the front right corner there is a socket at 45 degrees. The screws close to this socket can remain in place, but the plate to which the socket is attached must be released, and is secured by 1 x B and 1 x C.

· Central position: There is seminarcr’s hidden screw, type A. To see it a horizontal screw holding the plastic wire-carrying rail must be removed. This also type A

· Economics: I was quoted by a helpful company called CRC (in Woking) £20 for a set of absorbers and £40 for fitting plus VAT totalling £72 but I had to bring the machine in. I chose to ask them to post the absorbers to me.

· The base, containing all the absorbers, was extremely inky. I was pleased to find that lots of water and washing up liquid cleaned it very successfully.

· The new kit included a piece of plastic with an adhesive pad. Also the lower layer of the absorber that runs across the rear was slightly shorter, creating a space. I spoke to a helpful technician at CRC who told me that the plastic was a modification, and I should look out for a tube dangling from the bottom of the structure, in the right rear corner. The plastic will fit over the right side of the lateral absorber’s locating walls and below the plastic a small slot can be seen, into which the dangling tube should be inserted. I suggest the outside of the tube is cleaned using water and washing up liquid and vaselined for easy insertion.

· I found it difficult to insert seminarcr’s hidden screw when re-assembling. What is needed is the right sort of screwdriver with long thin shaft and strongly magnetic. My screwdriver was only slightly magnetic and the screw kept falling off and then into the bowels of the printer. A good policy is to insert this screw into position, with screwdriver in position and then lower the structure onto the base. Getting this screw sorted and getting the dangling tube into position simultaneously gave me some trouble.

· Having noted how easily a flow of soapy water would wash away the residual ink I experimented with washing my old absorbers. I think that for someone for whom money was scarcer than time the absorbers could be re-used.

I have a MX700 that is displaying a Code 5700 error. I know this is a paper feed issue. I have carefully inspected the paper feed paths , emptied a can of air, and still the machine won’t print. Suggestions please!